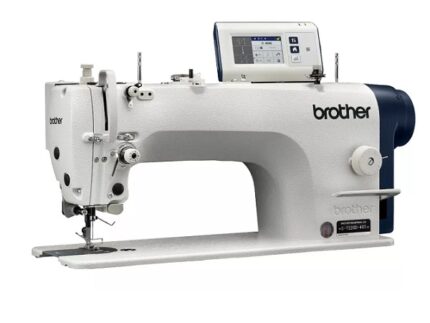

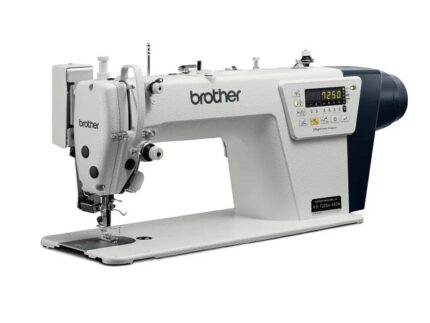

S-7220C

Single Needle Direct Drive Needle Feed Lock Stitcher with Thread Trimmer

- The needle feed mechanism prevents uneven material feeding

- Clean sewing with no oil staining

- Smooth sewing with direct drive system

- Energy-saving model

It prevents uneven material feeding, meeting the highest quality sewing standards.

Examples of suitable materials and processes : Sewing requiring quality, Slippery materials, Overlapping parts, Different materials, Lengthy articles, Materials difficult to feed

Prevents uneven material feeding

Movement is transmitted directly from the horizontal feed shaft, so that needle feed and lower feed are perfectly synchronized, preventing uneven material feeding for diversified materials.

Needle Breakage Prevention Function

When reverse stitching is carried out with the actuator switch, needle breakage may occur. With thorough analysis of its cause, the function preventing the needle breakage has been introduced.

Meets designs with long stitches

When the needle penetration resistance is increased in extra-thick overlapping part sewing, the needle penetration force is automatically increased by the vibration control (intermittent impact).

Specifications

| S-7220C- | 403 | 433 | 405 |

|---|---|---|---|

| Lubrication type | Minimum lubrication | Semi dry | Minimum lubrication |

| Application | Medium materials | Medium materials | Heavy materials |

| Max. sewing speed | 5,000 sti/min*1 | 4,000 sti/min | 4,000 sti/min*2 |

| Start backtacking and continuous backtacking speed | 220-3,000 sti/min | ||

| End backtacking speed | 1,800 sti/min | ||

| Max. stitch length | 4.5mm | 5.5mm | |

| Presser foot height | Presser bar lifter:6mm, knee lifter:16mm | ||

| Needle bar stroke | 33mm | 35mm | |

| Needle(DBx1・DPx5) | #11~#18 | #19~#22 | |

| Feed dog height | 1.0mm | 1.2mm | |

| Weight | Machine head: 46kg, Control box: 3.1kg, panel:0.6kg | ||

| Arm pocket size | Width:300mm, Height:120mm | ||

| Bed size | 517.5mm x 178mm | ||

| Power | Single phase 100-120V, 200-240V, 3-phase 200-240V, 380-415V | ||

Reviews

There are no reviews yet.